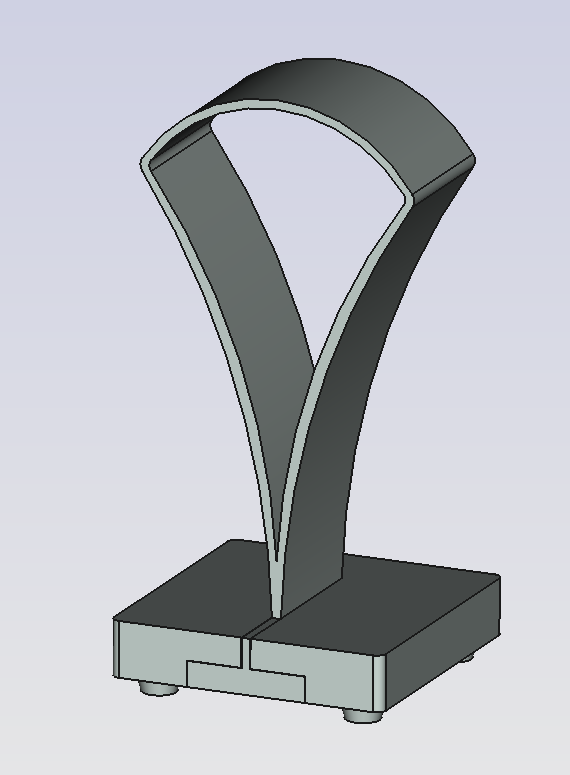

A (debatably) beautiful headphone stand.

Key Facts:

- Kick Off: 26.03.2025

- Finish: 04.04.2025

- approx. Cost: 90-100€

- Printables Files

A friend of mine sent me a picture of a headphone stand he had laid his eyes on for the past couple of weeks and asked me if we could (kind of) recreate it for cheaper.

So i tried.

A first recreation was quickly drawn up in a CAD-model, before realizing there will be some modifications needed for structural integrity.

A nearly 1:1 recreation would have been possible, but first tests proved the gut feeling of “this shit gonna’ be flimsy as hell”.

The original design is able to work due to the chosen material - some sort of metal - and it’s respective stirdiness.

Working with plastics however, the only way to at least tackle the deformation aspects was to bring symmetry into the desing.

Bearing the load on both sides eliminates the ability of the bow to fold in on itself.

Adding 1mm of width also increased the strength and reduced the bounciness of the hanger and with that being roughly sorted out, the design of the base began.

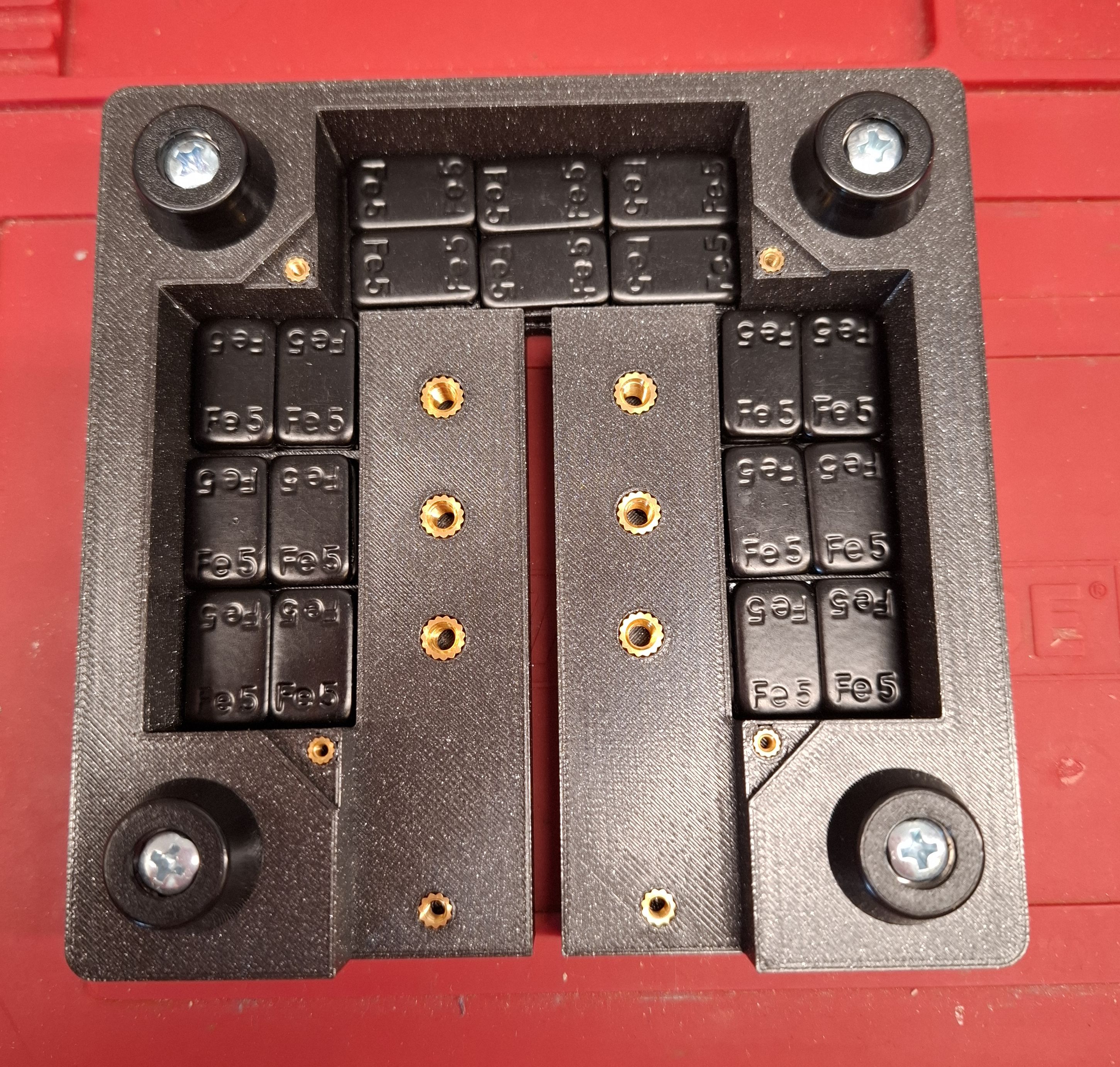

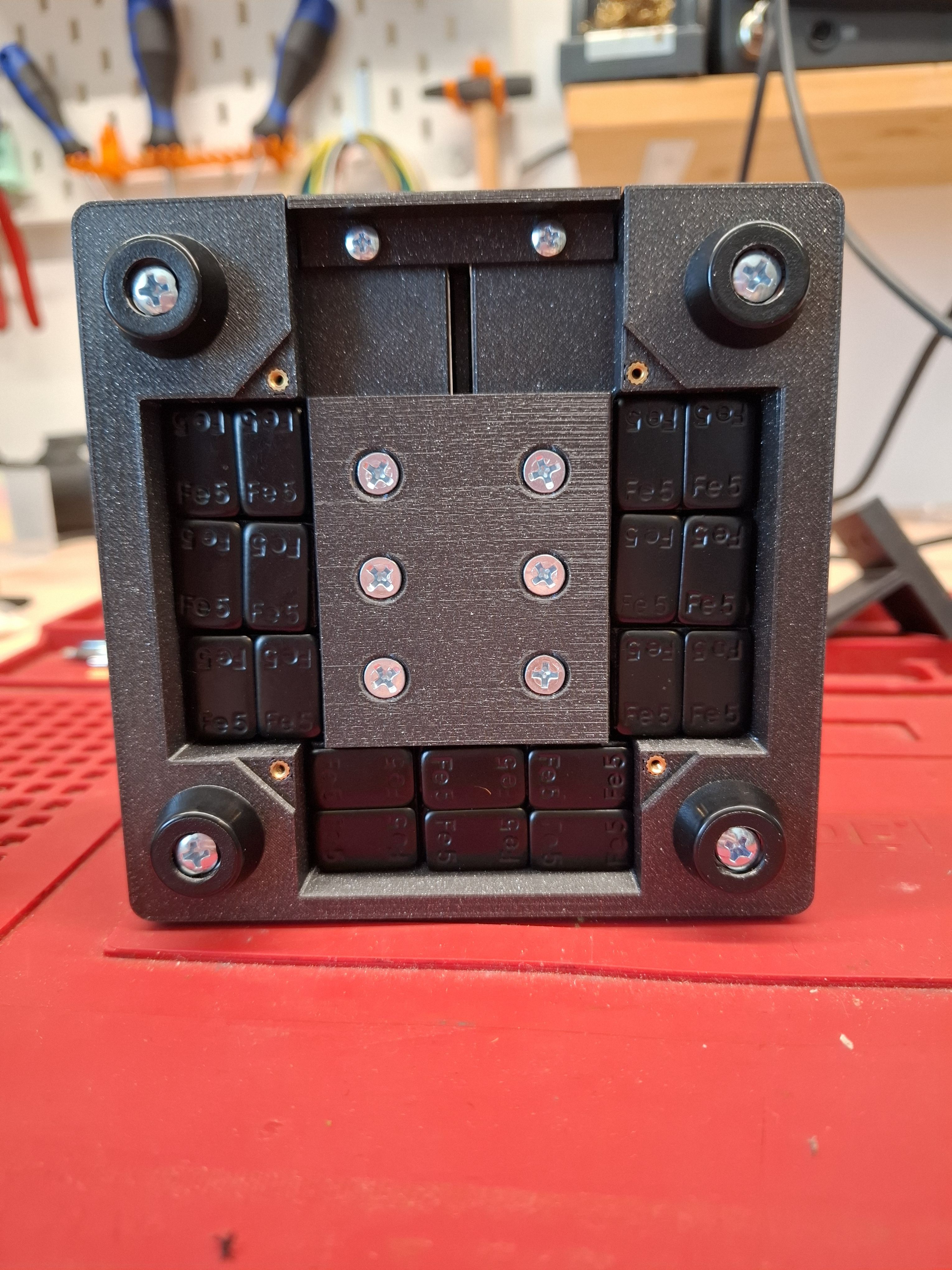

A slit from the middle outwards lets the hanger slide into the base. 6 4x12mm Screws mount the hanger in its designated location and hold it firmly against the base.

It became clear very quickly, that some kind of rubber feet would be a great addition to the design. Rubber Feet

Some sort of way to increase the base’ weight was needed. The original product and its inherent weight advantage helps it to be stury. Lead fishing weights were considered but soon disregarded for the lack of easy mounting options.

Tire balancing weights for RC toys turned out to work perfectly. With its preinstalled adhesive strips and rectangular shape, these will definitely become a new favourite in my toolbox. Mini-Weights

M2, M3 & M4 threaded inserts by rutex got installed. Ruthex Thread-Inserts

Two covers enclose the base, a front-cover closes up the slid on the top and backside. It gets mounted with 3x6mm screws.

The base-cover fits neatly into the remaining space, being held down with 2x5mm screws.

A small side-project which upped my engineering standards once again, with a couple of new things i will implement in lots of future designs.

Thanks for reading. ~Coni